BS4449 Steel Reinforcement Rebar

Classification :

Steel Rebar

Keywords :

Steel Rebar

PRODUCT DETAILS

BS4449 Steel Reinforcement Rebar Description

BS4449 is yet another deformed steel bar standard. It is also differentiated as per European standards. When it comes to manufacturing, the steel bars falling in this standard are also hot rolled, which means that they are also used for general purposes, i.e. in common construction projects. These deformed bars are also available between 12 mm to 30 mm diameter size. And the common lengths that they are available in are 9 m and 12 m. Though, it might vary highly.

| BS 4449:97 British Rebar Specifications | |||||||||||||||

| Rated Diameter |

Nominal Cross Section Area | Weight | EN To The Ribs (mm) | Longitudinal Ribs (mm) | Pitch / Step mm |

Ribs Tip Distance mm |

|||||||||

| Kg / m |

Tolerance % |

Height | Width | Height | Width | ||||||||||

| mm | m㎡ | min. | max. | min. | max. | min. | max. | min. | max. | min. | max. | min. | max. | ||

| 6 | 28.3 | 0.222 | ± 9 | 0.3 | 0.6 | 0.48 | 0.72 | 0.3 | 0.84 | 0.48 | 1.2 | 3,.0 | 4.8 | 1.5 | 2.3 |

| 8 | 50.3 | 0.395 | ± 6.5 | 0.4 | 0.8 | 0.64 | 0.96 | 0.4 | 0.84 | 0.64 | 1.6 | 4.0 | 6.4 | 2.0 | 3.1 |

| 10 | 78.5 | 0.616 | 0.5 | 1.0 | 0.8 | 1.2 | 0.5 | 0.84 | 0.8 | 2.0 | 5.0 | 8.0 | 2.5 | 3.9 | |

| 12 | 113.1 | 0.888 | ± 4.5 | 0.6 | 1.2 | 0.96 | 1.44 | 0.6 | 0.84 | 0.96 | 2.4 | 6.0 | 9.6 | 3.0 | 4.7 |

| 16 | 201.1 | 1.579 | 0.8 | 1.6 | 1.28 | 1.92 | 0.8 | 0.84 | 1.28 | 3.2 | 8.0 | 12.8 | 4.0 | 6.2 | |

| 20 | 314.2 | 2.466 | 1.0 | 2.0 | 1.6 | 2.4 | 1.0 | 0.84 | 1.6 | 4.0 | 10.0 | 16.0 | 5.0 | 7.8 | |

| 25 | 490.9 | 3.854 | 1.25 | 2.5 | 2.0 | 3.0 | 1.25 | 0.84 | 2.0 | 5.0 | 12.5 | 20.0 | 6.2 | 9.8 | |

| 32 | 804.2 | 6.313 | 1.60 | 3.2 | 2.56 | 3.84 | 1.60 | 0.84 | 2.56 | 6.4 | 16.0 | 25.6 | 8.0 | 12.5 | |

| 40 | 1256.6 | 9.864 | 2.0 | 4.0 | 3.2 | 4.8 | 2.0 | 0.84 | 3.2 | 8.0 | 20.0 | 32.0 | 10.0 | 15.7 | |

| 50 | 1963.5 | 15.413 | 2.5 | 5.0 | 4.0 | 6.0 | 2.5 | 0.84 | 4.0 | 10.0 | 25.0 | 40.0 | 12.5 | 19.6 | |

| BS 4449:97 Steel Rebar Mechanical Properties | ||||

| Quality |

Akma N / mm2< | Akma / Pull Rate N/mm2 | Elongation Elasticity | Total max. % AGT |

| min. | min. | min. | min. | |

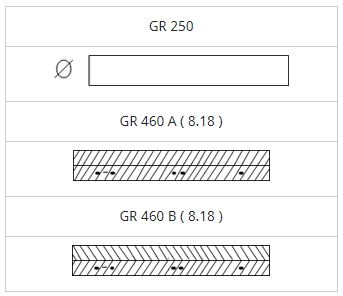

| GR 250 | 250 | Akma x 1.15 | 22 | – |

| GR 460 A | 460 | Akma x 1.05 | 12 | 2.5 |

| GR 460 B | 460 | Akma x 1.08 | 14 | 5 |

| BS 4449:97 Steel Rebar Chemical Properties | |||||

| Element | GR 250 % max. | GR 460 A / B % max. | Ribs and Marking Method | ||

| Casting | Product | Casting | Product |  |

|

| C | 0.25 | 0.27 | 0.25 | 0.27 | |

| P | 0.060 | 0.065 | 0.050 | 0.055 | |

| S | 0.060 | 0.065 | 0.050 | 0.055 | |

| N | 0.012 | 0.013 | 0.012 | 0.013 | |

| CE | 0.42 | 0.45 | 0.51 | 0.54 | |

| Mn Cr+Mo+V Ni+Cu | |||||

| CE = C + ————- + ——————- + —————– | |||||

| 6 5 15 | |||||

Scope of Application

Widely used in houses, bridges, roads, especially railways and other civil engineering.

| USA | Japan | Germany | U.K. |

|

France | Italy | Spain | Switzerland | China | |

|

AISI/SAE |

JIS |

W‐nr. |

DIN |

BS |

EN |

AFNOR |

UNI |

UNE |

SS |

GB |

|

A570.36 |

STKM 12A |

1.0038 |

RSt.37‐2 |

4360 |

‐ |

E 24‐2 |

‐ |

‐ |

1311 |

15 |

|

- |

STKM 12C |

- |

- |

40 C |

- |

Ne |

- |

- |

- |

- |

|

1015 |

‐ |

1.0401 |

C15 |

080M15 |

‐ |

CC12 |

C15, C16 |

F.111 |

1350 |

15 |

|

1020 |

‐ |

1.0402 |

C22 |

050A20 |

2C |

CC20 |

C20, C21 |

F.112 |

1450 |

20 |

|

1213 |

SUM22 |

1.0715 |

9SMn28 |

230M07 |

1A |

S250 |

CF9SMn28 |

F.2111 |

1912 |

Y15 |

|

11SMn28 |

||||||||||

|

12L13 |

SUM22L |

1.0718 |

9SMnPb28 |

‐ |

‐ |

S250Pb |

CF9SMnPb28 |

11SMnPb28 |

1914 |

‐ |

|

‐ |

‐ |

1.0722 |

10SPb20 |

‐ |

‐ |

10PbF2 |

CF10Pb20 |

10SPb20 |

‐ |

‐ |

|

1215 |

‐ |

1.0736 |

9SMn36 |

240M07 |

1B |

S300 |

CF9SMn36 |

12SMn35 |

‐ |

Y13 |

|

12L14 |

‐ |

1.0737 |

9SMnPb36 |

‐ |

‐ |

S300PB |

CF9SMnPb36 |

12SMnP35 |

1926 |

‐ |

|

1015 |

S15C |

1.1141 |

Ck15 |

080M15 |

32C |

XC12 |

C16 |

C15K |

1370 |

15 |

|

1025 |

S25C |

1.1158 |

Ck25 |

‐ |

‐ |

‐ |

‐ |

‐ |

‐ |

25 |

|

A572-60 |

‐ |

1.890 |

StE380 |

4360 55 |

‐ |

‐ |

FeE390KG |

‐ |

2145 |

‐ |

|

1035 |

‐ |

1.0501 |

C35 |

060A35 |

‐ |

CC35 |

C35 |

F.113 |

1550 |

35 |

|

1045 |

‐ |

1.0503 |

C45 |

080M46 |

‐ |

CC45 |

C45 |

F.114 |

1650 |

45 |

|

1140 |

‐ |

1.0726 |

35S20 |

212M36 |

8M |

35MF4 |

‐ |

F210G |

1957 |

‐ |

|

1039 |

‐ |

1.1157 |

40Mn4 |

150M36 |

15 |

35M5 |

‐ |

‐ |

‐ |

40Mn |

|

1335 |

SMn438(H) |

1.1167 |

36Mn5 |

‐ |

‐ |

40M5 |

‐ |

36Mn5 |

2120 |

35Mn2 |

|

1330 |

SCMn1 |

1.1170 |

28Mn6 |

150M28 |

14A |

20M5 |

C28Mn |

‐ |

‐ |

30Mn |

|

1035 |

S35C |

1.1183 |

Cf35 |

060A35 |

‐ |

XC38TS |

C36 |

‐ |

1572 |

35Mn |

|

1045 |

S45C |

1.1191 |

Ck45 |

080M46 |

‐ |

XC42 |

C45 |

C45K |

1672 |

Ck45 |

|

1050 |

S50C |

1.1213 |

Cf53 |

060A52 |

‐ |

XC48TS |

C53 |

‐ |

1674 |

50 |

|

1055 |

‐ |

1.0535 |

C55 |

070M55 |

9 |

‐ |

C55 |

‐ |

1655 |

55 |

|

1060 |

‐ |

1.0601 |

C60 |

080A62 |

43D |

CC55 |

C60 |

‐ |

‐ |

60 |

|

1055 |

S55C |

1.1203 |

Ck55 |

070M55 |

‐ |

XC55 |

C50 |

C55K |

‐ |

55 |

|

1060 |

S58C |

1.1221 |

Ck60 |

080A62 |

43D |

XC60 |

C60 |

‐ |

1678 |

60Mn |

|

1095 |

‐ |

1.1274 |

Ck101 |

060A96 |

‐ |

XC100 |

‐ |

F.5117 |

1870 |

‐ |

|

W1 |

SK3 |

1.1545 |

C105W1 |

BW1A |

‐ |

Y105 |

C36KU |

F.5118 |

1880 |

‐ |

|

W210 |

SUP4 |

1.1545 |

C105W1 |

BW2 |

‐ |

Y120 |

C120KU |

F.515 |

2900 |

‐ |

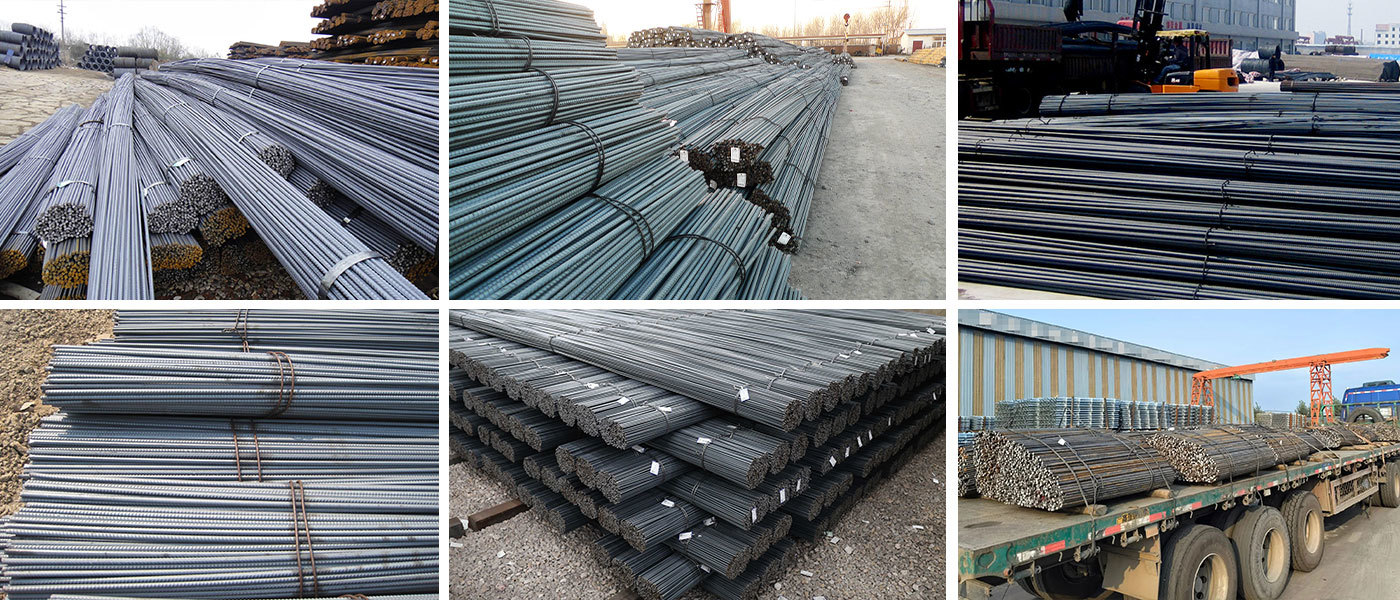

Packing and delivery

Established in 2005, we are a key steel manufacturer boasting a 400,000㎡ production site and an annual output of 2.5 million tons. Our offerings span mild steel, alloy plates, coated steel coils, and welded pipes, serving industries like machinery, shipbuilding, and infrastructure.

Customer Visit

Our market reach covers 25+ nations, with a focus on building enduring client partnerships through consistent supply and responsive service. Dedicated to progress and eco-friendliness, we prioritize tech upgrades and low-carbon production to fuel sector development.

HONOR

Certified by ISO 9001, SGS, and API, we guarantee top-tier quality and safety. Our market reach covers 25+ nations, with a focus on building enduring client partnerships through consistent supply and responsive service.

APPLICATION

Ship

Chemical Industry

Electricity

Oil and gas transportation

FAQ

RELATED PRODUCTS

GET A FREE QUOTE