A106 Grade B Steel Pipe

Classification :

Carbon Steel Pipe

Keywords :

Carbon Steel Pipe

PRODUCT DETAILS

A106 Grade B Steel Pipe Description

ASTM A106 is suitable for seamless carbon steel pipe for high temperature environment. ASTM A106 pipe is manufactured according to grade A, B and C. A106-A is equivalent to the domestic 10# steel material, A106-B is equivalent to the domestic 20# material, is a relatively common use of a steel pipe material at home and abroad. A106 seamless steel pipe is mainly used in construction, mechanical processing, electrical, petrochemical and other industries.

Product Parameters

Product Name | A106 Grade B Steel Pipe | |

Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI etc. | |

Outer Diameter | Seamless: 1/4"-36" | Welding: 21.3mm-3620mm |

Round Tube: 1/2"-10" | Square Tube/Rectangular Tube: 15x15mm-400x600mm | |

Wall Thickness | Seamless: 1.25mm-50mm | Welding: 1.65mm-65mm |

Length | 3-12 meters, Support customization | |

Surface Process | Bright, Polished, Black | |

Other Services | Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. | |

Chemical Composition

A106 | C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

GradeA | 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

GradeB | 0.30 | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

GradeC | 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

Mechanical Properties

A106 | GradeA | GradeB | GradeC |

Tensile Strength min.psi | 48,000 | 60,000 | 70,000 |

Yield Strength min.psi | 30,000 | 35,000 | 40,000 |

Scope of Application

ASTM A106 seamless pressure pipe (also known as ASME SA106 pipe) is commonly used in the construction of oil and gas refineries, power plants, petrochemical plants, boilers and ships. These pipes must transport fluids and gases with high temperature and pressure levels.

| USA | Japan | Germany | U.K. |

|

France | Italy | Spain | Switzerland | China | |

|

AISI/SAE |

JIS |

W‐nr. |

DIN |

BS |

EN |

AFNOR |

UNI |

UNE |

SS |

GB |

|

A570.36 |

STKM 12A |

1.0038 |

RSt.37‐2 |

4360 |

‐ |

E 24‐2 |

‐ |

‐ |

1311 |

15 |

|

- |

STKM 12C |

- |

- |

40 C |

- |

Ne |

- |

- |

- |

- |

|

1015 |

‐ |

1.0401 |

C15 |

080M15 |

‐ |

CC12 |

C15, C16 |

F.111 |

1350 |

15 |

|

1020 |

‐ |

1.0402 |

C22 |

050A20 |

2C |

CC20 |

C20, C21 |

F.112 |

1450 |

20 |

|

1213 |

SUM22 |

1.0715 |

9SMn28 |

230M07 |

1A |

S250 |

CF9SMn28 |

F.2111 |

1912 |

Y15 |

|

11SMn28 |

||||||||||

|

12L13 |

SUM22L |

1.0718 |

9SMnPb28 |

‐ |

‐ |

S250Pb |

CF9SMnPb28 |

11SMnPb28 |

1914 |

‐ |

|

‐ |

‐ |

1.0722 |

10SPb20 |

‐ |

‐ |

10PbF2 |

CF10Pb20 |

10SPb20 |

‐ |

‐ |

|

1215 |

‐ |

1.0736 |

9SMn36 |

240M07 |

1B |

S300 |

CF9SMn36 |

12SMn35 |

‐ |

Y13 |

|

12L14 |

‐ |

1.0737 |

9SMnPb36 |

‐ |

‐ |

S300PB |

CF9SMnPb36 |

12SMnP35 |

1926 |

‐ |

|

1015 |

S15C |

1.1141 |

Ck15 |

080M15 |

32C |

XC12 |

C16 |

C15K |

1370 |

15 |

|

1025 |

S25C |

1.1158 |

Ck25 |

‐ |

‐ |

‐ |

‐ |

‐ |

‐ |

25 |

|

A572-60 |

‐ |

1.890 |

StE380 |

4360 55 |

‐ |

‐ |

FeE390KG |

‐ |

2145 |

‐ |

|

1035 |

‐ |

1.0501 |

C35 |

060A35 |

‐ |

CC35 |

C35 |

F.113 |

1550 |

35 |

|

1045 |

‐ |

1.0503 |

C45 |

080M46 |

‐ |

CC45 |

C45 |

F.114 |

1650 |

45 |

|

1140 |

‐ |

1.0726 |

35S20 |

212M36 |

8M |

35MF4 |

‐ |

F210G |

1957 |

‐ |

|

1039 |

‐ |

1.1157 |

40Mn4 |

150M36 |

15 |

35M5 |

‐ |

‐ |

‐ |

40Mn |

|

1335 |

SMn438(H) |

1.1167 |

36Mn5 |

‐ |

‐ |

40M5 |

‐ |

36Mn5 |

2120 |

35Mn2 |

|

1330 |

SCMn1 |

1.1170 |

28Mn6 |

150M28 |

14A |

20M5 |

C28Mn |

‐ |

‐ |

30Mn |

|

1035 |

S35C |

1.1183 |

Cf35 |

060A35 |

‐ |

XC38TS |

C36 |

‐ |

1572 |

35Mn |

|

1045 |

S45C |

1.1191 |

Ck45 |

080M46 |

‐ |

XC42 |

C45 |

C45K |

1672 |

Ck45 |

|

1050 |

S50C |

1.1213 |

Cf53 |

060A52 |

‐ |

XC48TS |

C53 |

‐ |

1674 |

50 |

|

1055 |

‐ |

1.0535 |

C55 |

070M55 |

9 |

‐ |

C55 |

‐ |

1655 |

55 |

|

1060 |

‐ |

1.0601 |

C60 |

080A62 |

43D |

CC55 |

C60 |

‐ |

‐ |

60 |

|

1055 |

S55C |

1.1203 |

Ck55 |

070M55 |

‐ |

XC55 |

C50 |

C55K |

‐ |

55 |

|

1060 |

S58C |

1.1221 |

Ck60 |

080A62 |

43D |

XC60 |

C60 |

‐ |

1678 |

60Mn |

|

1095 |

‐ |

1.1274 |

Ck101 |

060A96 |

‐ |

XC100 |

‐ |

F.5117 |

1870 |

‐ |

|

W1 |

SK3 |

1.1545 |

C105W1 |

BW1A |

‐ |

Y105 |

C36KU |

F.5118 |

1880 |

‐ |

|

W210 |

SUP4 |

1.1545 |

C105W1 |

BW2 |

‐ |

Y120 |

C120KU |

F.515 |

2900 |

‐ |

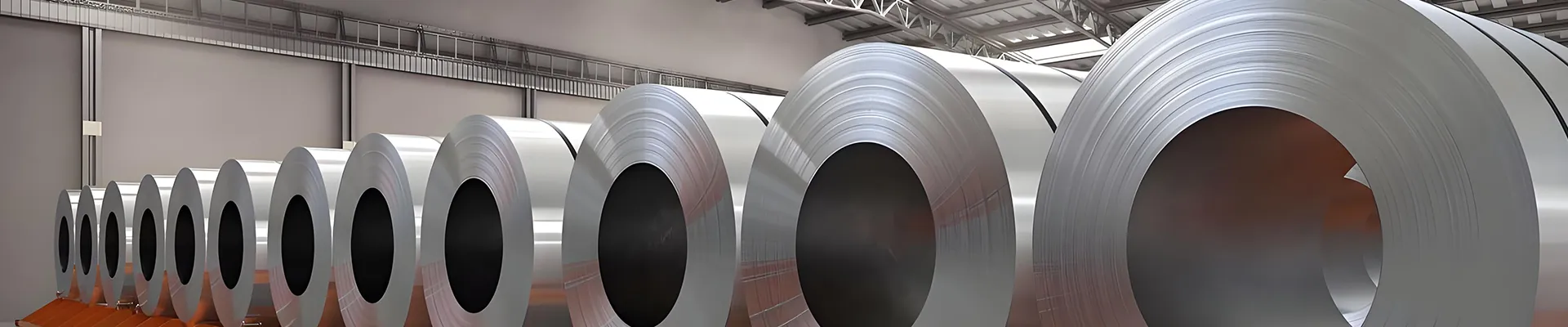

Packing and delivery

Established in 2005, we are a key steel manufacturer boasting a 400,000㎡ production site and an annual output of 2.5 million tons. Our offerings span mild steel, alloy plates, coated steel coils, and welded pipes, serving industries like machinery, shipbuilding, and infrastructure.

Customer Visit

Our market reach covers 25+ nations, with a focus on building enduring client partnerships through consistent supply and responsive service. Dedicated to progress and eco-friendliness, we prioritize tech upgrades and low-carbon production to fuel sector development.

HONOR

Certified by ISO 9001, SGS, and API, we guarantee top-tier quality and safety. Our market reach covers 25+ nations, with a focus on building enduring client partnerships through consistent supply and responsive service.

APPLICATION

Ship

Chemical Industry

Electricity

Oil and gas transportation

FAQ

RELATED PRODUCTS

GET A FREE QUOTE